How digitalisation facilitates material reuse in construction

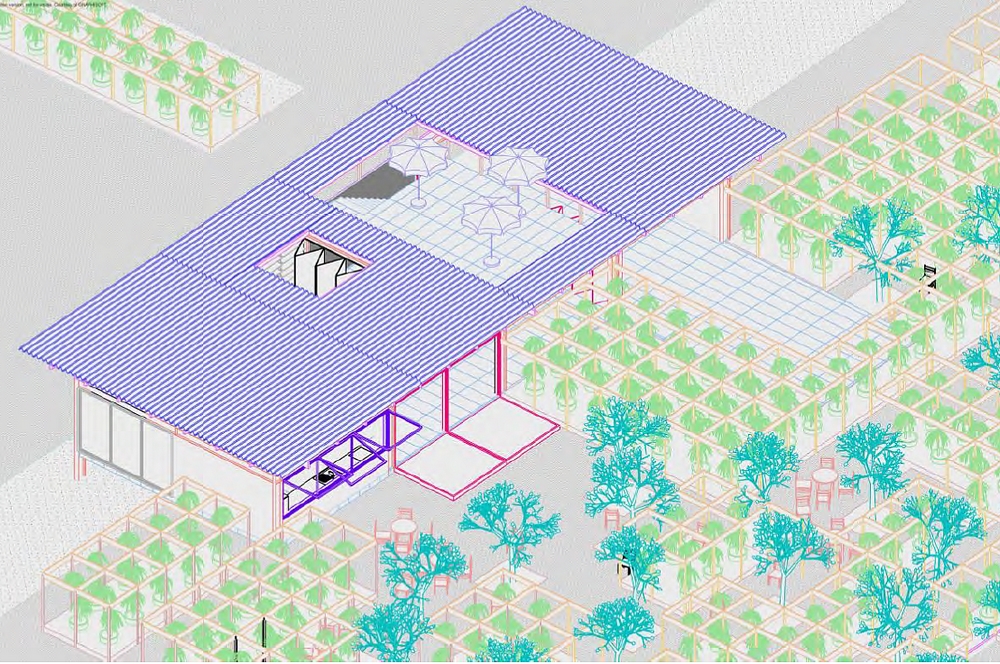

The "Petite maison" project, inaugurated in mid-September, also provided input to a thematic day around circularity and reuse in construction.

Jean-Michel Gaudron

Jean-Michel Gaudron

Building while preserving a maximum of value for each of the elements used so that they can potentially be reused later: this is the common thread of the “Petite maison” project, officially inaugurated in mid-September. “But the standards change so frequently that it is difficult to know how to do it right,” explained architect Carole Schmit, who is behind the “Petite maison” project, while opening the roundtable workshop organised this Wednesday on the theme of circularity and reuse in construction. Some 60 people participated in the event. “This project shows what the architecture of the future could look like and what attitude designers will have to adopt to make the principles of circular construction both affordable and attractive to users.”

Building while preserving a maximum of value for each of the elements used so that they can potentially be reused later: this is the common thread of the “Petite maison” project, officially inaugurated in mid-September. “But the standards change so frequently that it is difficult to know how to do it right,” explained architect Carole Schmit, who is behind the “Petite maison” project, while opening the roundtable workshop organised this Wednesday on the theme of circularity and reuse in construction. Some 60 people participated in the event. “This project shows what the architecture of the future could look like and what attitude designers will have to adopt to make the principles of circular construction both affordable and attractive to users.”

The key word that emerged from all the debates and discussions during the workshop is undoubtedly “digitalisation”. It is deeply ingrained into all stages of the reflection on the best way to recover materials and waste.

The waste law of 21 March 2012, presented by Yannick Pau, Project Officer at the Ministry of Environment, Climate and Sustainable Development, and Vishojit B. Thapa, Senior Research Officer in the Strategy and Concepts Unit of the Environment Administration, was amended in June 2022 to better respond to the realities on the ground.

For example, article 26 provides for an extension of the modalities concerning the inventory of materials to be deconstructed that project managers must establish before any deconstruction for a built volume superior to 1,200 m3 (and a waste volume superior to 100 m3). If the built volume exceeds 3,500 m3, the inventory needs to be established by an approved organisation. A guide with an Excel model of the existing inventory is available to interested companies.

This article 26 also provides for the setting up of a computerised register of construction materials, to be established by the project manager for the construction of buildings exceeding 3,500 m3 built after 1 January 2025. A Grand Ducal regulation is being prepared to specify the implementation of such a computerised register.

For a better visibility of available resources

The InterReg NWE project “Digital Deconstruction” was at the heart of this workshop/roundtable. Its aim is to promote the development of an innovative platform integrating various digital tools in order to facilitate circular deconstruction.

The InterReg NWE project “Digital Deconstruction” was at the heart of this workshop/roundtable. Its aim is to promote the development of an innovative platform integrating various digital tools in order to facilitate circular deconstruction.

“Most of the time, we don’t have any technical information, BI model or inventory for the buildings we work on,” explained Jean-Yves Marié, CEO of BIM-Y, a company specialised in digital modelling of all types of buildings. “We can scan up to 12,000 m2 of surfaces per day, taking a picture every 1.5-2 metres inside the buildings, and detect ‘objects’ such as doors, windows, lifts, lighting, sensors etc. Using artificial intelligence tools, we can then restructure all this data into a whole that can be reused and modelled.”

Among other benefits, this approach allows for better planning of future construction sites by identifying the availability of resource based on scheduled deconstruction of other buildings. “This makes it possible to rely on a more global management and to define certain urban deposits (for concrete or steel) and better understand what resources a territory has.”

The “Digital Deconstruction” project brings together 14 French, Belgian, Dutch and Luxembourg partners. In the Grand Duchy, the figures speak for themselves: in 2020, construction and demolition waste represented some 9 million tons (of which approximately 7 million consisted of excavated earth). Less than 3% is considered for reuse. “Digitisation is an essential element for the reuse of these materials,” said Dr Arch. Annie Guerriero, project coordinator at the Luxembourg Institute for Science and Technology. “But there are some major challenges, such as the management of a large quantify of information of different nature and format that makes modelling difficult.

Digital… but not only!

But digital is not everything either. A material is sometimes cumbersome and complicated to store. Guillaume Dubois, Executive Director at Schroeder & Associés, testified to this by talking about the demolition site of the Ettelbruck station. “We had subjectively identified the materials likely to be interesting to recover. But in the end, we collected more interesting materials than we thought. The Architectural Heritage Institute also identified materials that it found relevant. Otherwise, we might have missed some things. The organisation and timing of the sites are very important to ensure the storage of materials, and can have a great influence on the deadlines. A big step forward that could save time and energy is obviously the digitisation of information that would then allow us to work very early in a project.”

But digital is not everything either. A material is sometimes cumbersome and complicated to store. Guillaume Dubois, Executive Director at Schroeder & Associés, testified to this by talking about the demolition site of the Ettelbruck station. “We had subjectively identified the materials likely to be interesting to recover. But in the end, we collected more interesting materials than we thought. The Architectural Heritage Institute also identified materials that it found relevant. Otherwise, we might have missed some things. The organisation and timing of the sites are very important to ensure the storage of materials, and can have a great influence on the deadlines. A big step forward that could save time and energy is obviously the digitisation of information that would then allow us to work very early in a project.”

The problem of storage was also encountered by Rotor Déconstruction, a Brussels-based cooperative company active since 2014 in the recovery and resale of modern and contemporary building materials and finishing elements. “When starting our activities, we thought we would be smarter by not having any stock, but we had to rent a warehouse very quickly as it gives us room to negotiate contracts. It also fed our online store,” explained Michaël Ghyoot, Architect and Project Coordinator at Rotor asbl. “Our clientele is made up of one-third private individuals, one-third designers, interior architects who work for the design of hotels, restaurants and public spaces and one-third construction contractors who come to buy lots of materials.”

Social purpose cooperative Retrival, which was created 25 years ago by steelmaker Cockerill, has made waste and deconstruction its daily business. “You can’t learn these two areas in school,” explained its Director Damien Verraver. “You have to get your hands into it. You have to feel it. Just because you know how to put a door together doesn’t mean you can take it apart. Reusing equipment is clearly a new profession. We have expanded our business beyond just the materials we deconstruct ourselves. In the summer of 2021, we launched our digital and physical platform for reselling all the materials we have in stock.”

What business model?

There is clearly an economic dimension to take into account, knowing that, as Mr Verraver pointed out, “a digital platform for reuse materials is not viable on its own.” Hence the importance of looking at the issue as a whole, identifying material deposits further upstream and transforming them. “This is the added value that makes it possible to generate benefits. There is not necessarily a right or wrong solution. As long as we’re doing something, it’s good.”

The second round table, including Christian Rech (Ing. dipl. Proxyholder at Cimalux), Laurent Nilles (managing director of Prefalux) and Christophe Odenbreit (professor at the University of Luxembourg), emphasised that, basically, building is never an ecological act as such. Hence the need to focus on prefabrication and more standardisation, in order to be able to do more with less… and to favour less energy consuming materials such as wood. Dismountability and robustness are also two essential factors that must be taken into account. One thing is constant: do not consider the final price of the construction site as the main criterion of choice.

The lack of qualified manpower and the emergence of new professions such as assemblers were also addressed, in a context of increasing tension on the job market in the construction sector.

During this very instructive day, the participants also had the opportunity to take a guided tour of the Petite maison, which stands in front of the University in Belval.